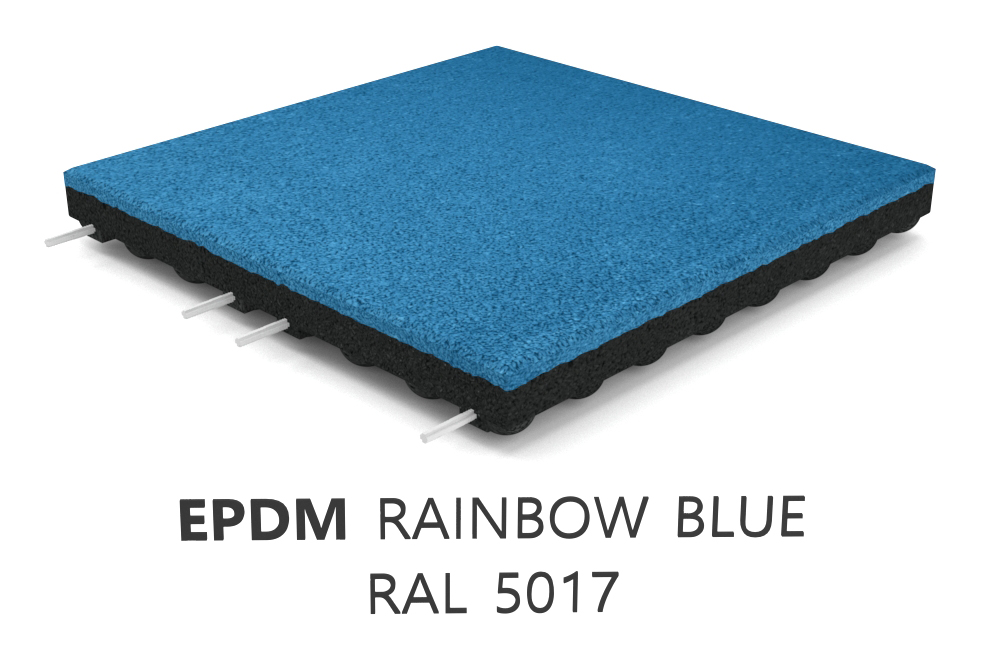

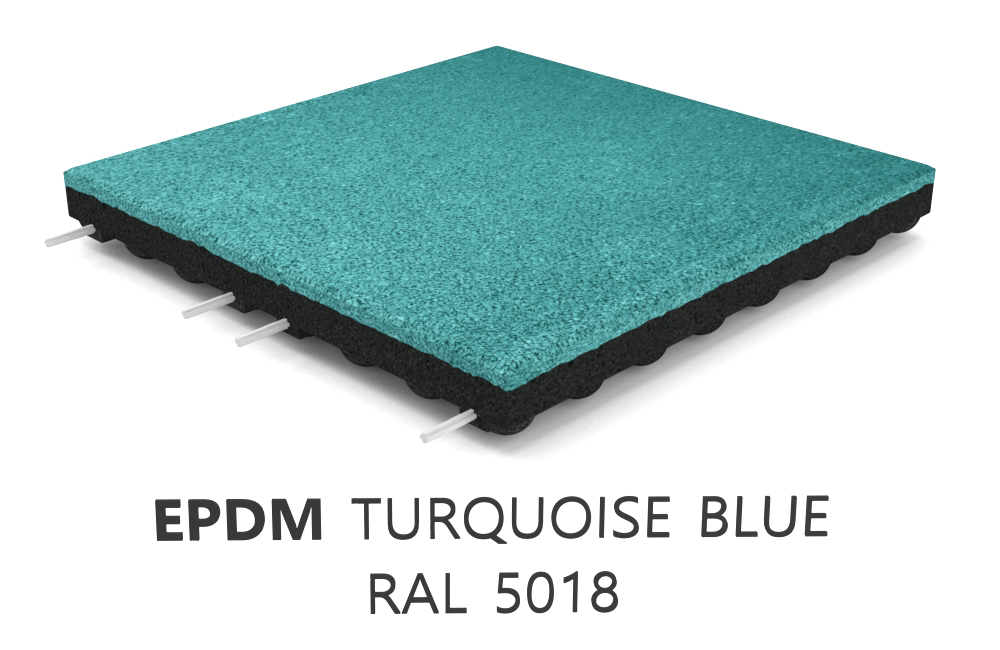

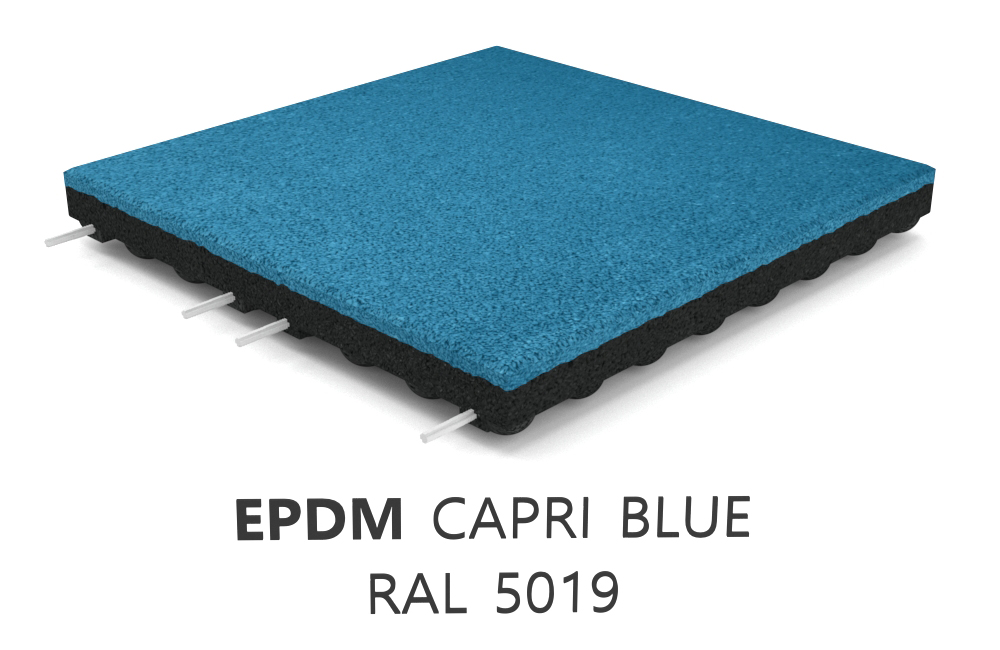

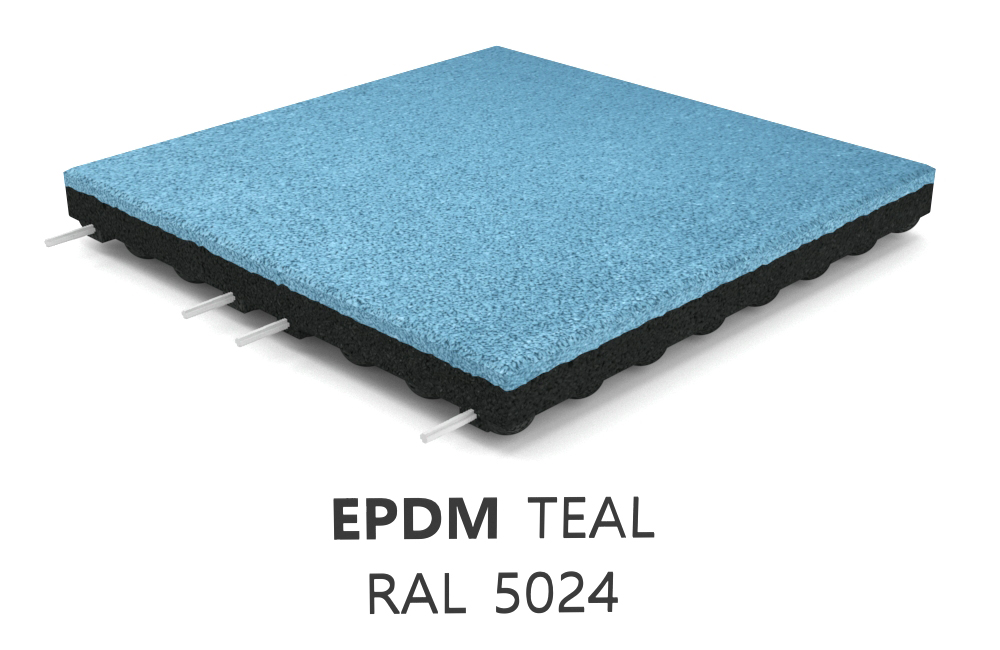

Playgruound flooring – EPDM Rubber Playground Tiles

EPDM fall protection tiles are safe and cost-effective – the optimal combination of safety, durability and unusual colours

EPDM tiles are ideal for places where the surface must meet strict safety standards and have above-average durability and aesthetic appearance. The tiles are highly recommended in areas exposed to permanent sunlight. They are resistant to intensive use.

Elastic surface with increased resistance for special requirements

The Flexizone EPDM tiles have the same advantages as the Flexizone SBR tiles – they have an elastic and non-slip surface, they break falls and minimise the risk of abrasions and injuries – and in addition:

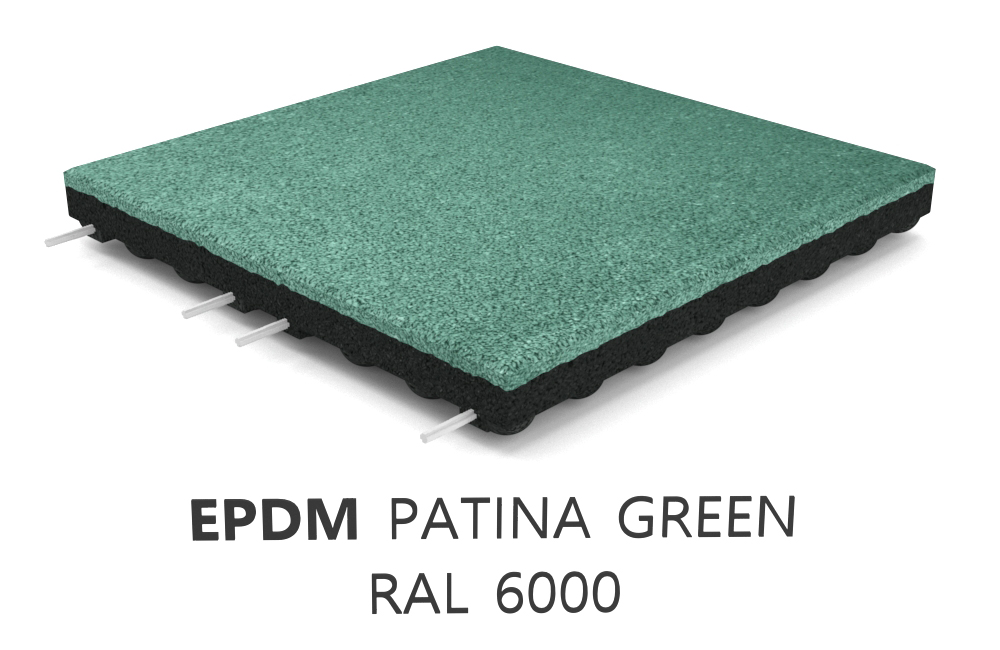

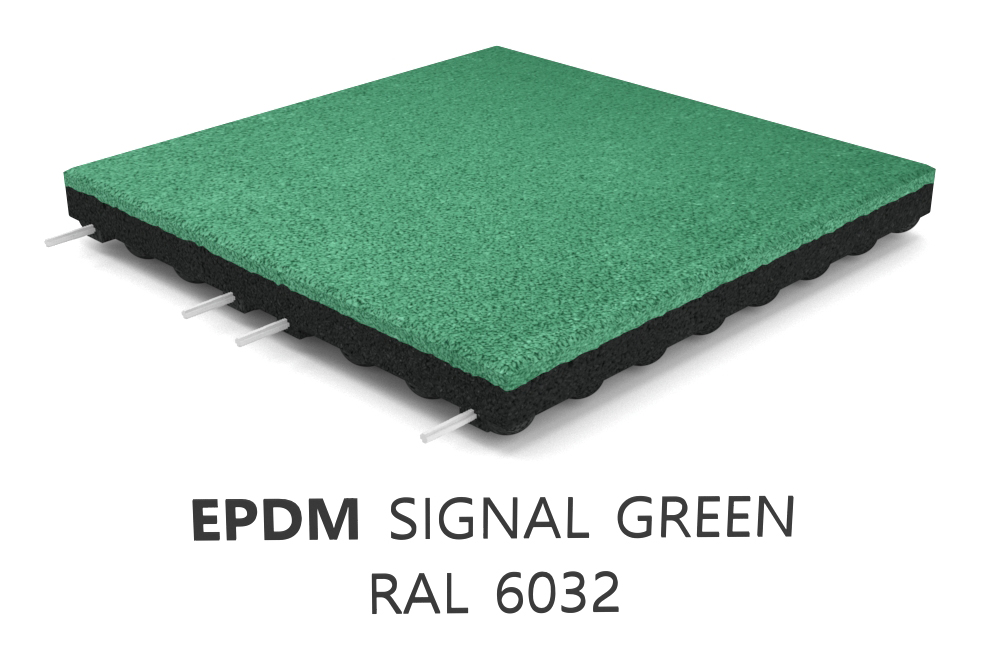

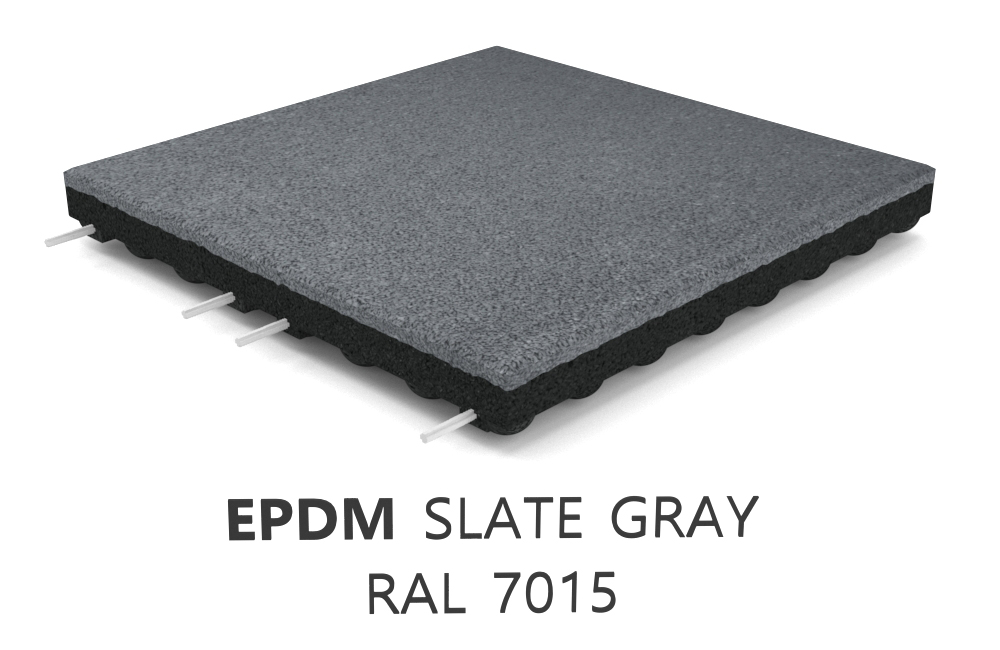

- they are available in a wide range of 24 RAL colours

- the technology of spinning dyeing guarantees high paint abrasion resistance, which is especially important for stressed areas

- UV resistance prevents colour fading

- Increased resistance of the EPDM coating to thermal ageing caused by extreme temperatures extends the life of the tiles up to several years without loss of elasticity and aesthetic look.

24 durable colours – the power of colourful composition

Safe and colourful rubber flooring in the form of modules – for all conditions and for many seasons

EPDM is UV-resistant and resistant to frost and intense sunshine, which means that the EPDM tiles can be used in open environments and in high-traffic areas. They do not need to be dismantled for winter and retain their colour and chemical stability for many seasons.

Quick installation in large areas

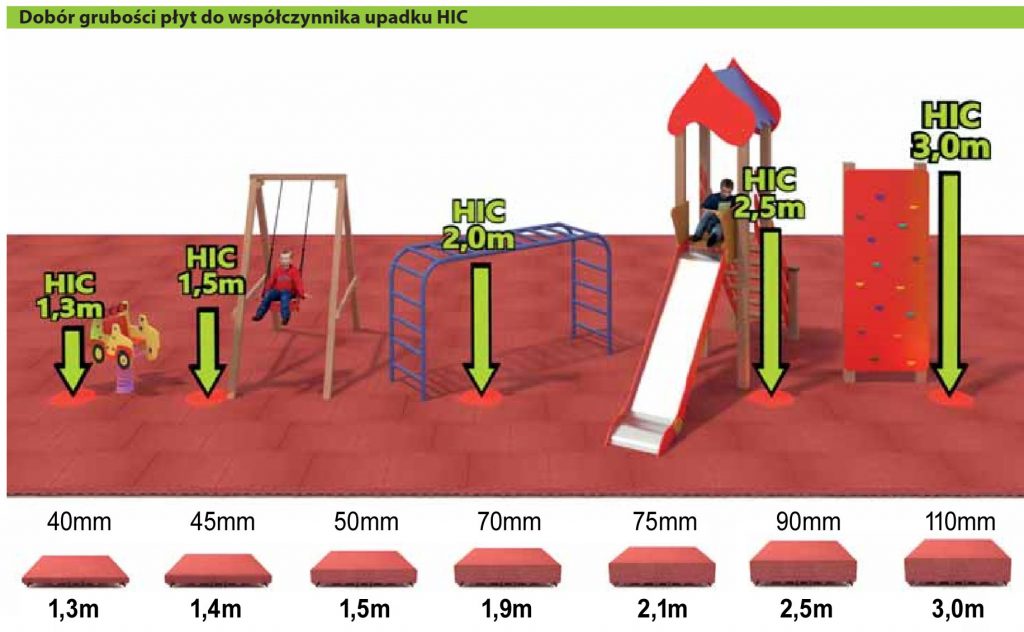

EPDM tiles are available in two standard sizes, which makes them easy to install in large areas. They are manufactured in eight thickness variants, which must always be adapted to the required HIC value (critical fall height).

They can be installed in the standard or the so-called “folding” system. 16 points of corrugated pins guarantee a tight connection of the tiles and eliminate the effect of curling the edges.

Proper surface preparation is of great importance. The ground should be level and stable. We recommend watching the specially prepared instructional video.

- 500 mm x 500 mm

- 610 mm x 610 mm