SBR Tiles

SBR rubber tiles and mats for the playgrounds

It is a synthetic rubber that, as a result of an automated colouring process, is more resistant to abrasion and adverse weather than natural rubber.

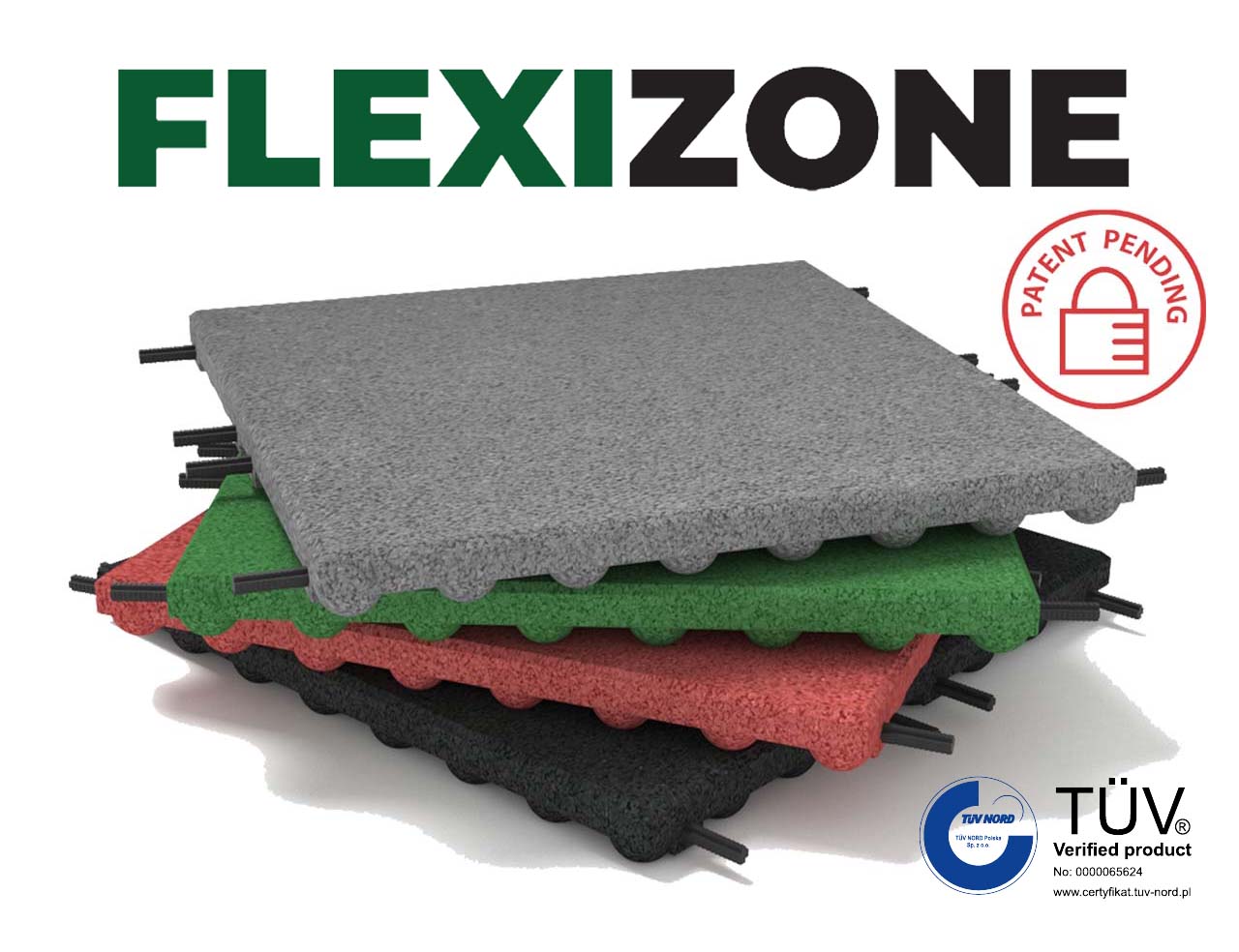

We produce SBR tiles from the black granulate recycled from conventional rubber tyres. During production, it is thoroughly cleaned and stripped of metal cords. Its suitability for reuse is certified by the National Institute of Public Health (PZH). The black base can be pigmented in one of three available colours, i.e. (brick) red, green and grey. However, all the tiles up to a thickness of 50 mm are made in a single-colour version, which means that the entire tile has one colour, and the hazardous effect of corner warping is avoided.

Thanks to their shock-absorbing properties, these tiles can be used in areas with an increased risk of falls and serious injuries. They are ideal for, among others, outdoor playgrounds, educational areas, outdoor sports facilities, gyms, jogging paths and care homes, as well as terraces, balconies and patios.

The SBR granulate is also used to make rubber pads for joists, insulating structural timber components from the substrate. Another advantage is their vibration insulation. You can dampen and reduce floor, terrace and industrial machinery vibrations with them.

Play carefree. Sports and leisure without injuries.

Why are the Flexizone’s SBR playground flooring tiles worth using?

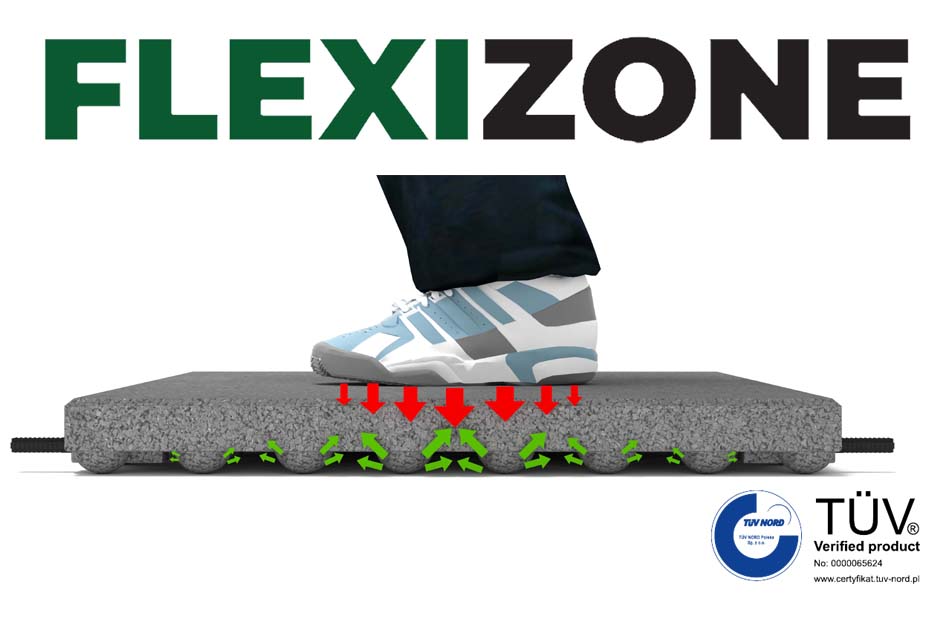

- both elastic and stable rubber mats for the playground reduce the risk of abrasions and injuries

- the special drainage system accelerates the drying of the material and prevents the formation of puddles

- the slightly porous structure ensures anti-slip properties. The soft surface structure of the tiles is pleasant and barefoot-friendly

- SBR copolymer is easy to keep clean – all you need is water and possibly a mild detergent or pressure washer

- payground flooring rubber tiles are resistant to abrasion, tearing and temperature fluctuations in the range of -30⁰C to 70⁰C

- playground rubber tiles maintain structural stability and are not subject to permanent deformation under standard loads.

Universal colors fit any landscape.

Safe rubber tiles with a wide range of applications.

Due to the size and precision of the individual elements, which allow for easy and quick installation, SBR panels are recommended for large areas.

PLAYGROUNDS

The safety and quality of Flexizone SBR tiles have been confirmed by numerous certificates. Bright colours and a pleasant material favour carefree fun.

SPORTS FACILITIES

Shock absorption and anti-slip properties reduce the risk of injury. High soundproofing reduces noise.

PUBLIC FACILITIES

The ease of assembly and replacement of the individual components. Tiles are resistant to mechanical damage and have low sensitivity to temperature fluctuations.

TERRACES AND PATIOS

The vibration isolation and damping properties make the tiles pleasant to walk barefoot.

Two sizes and two types of installation.

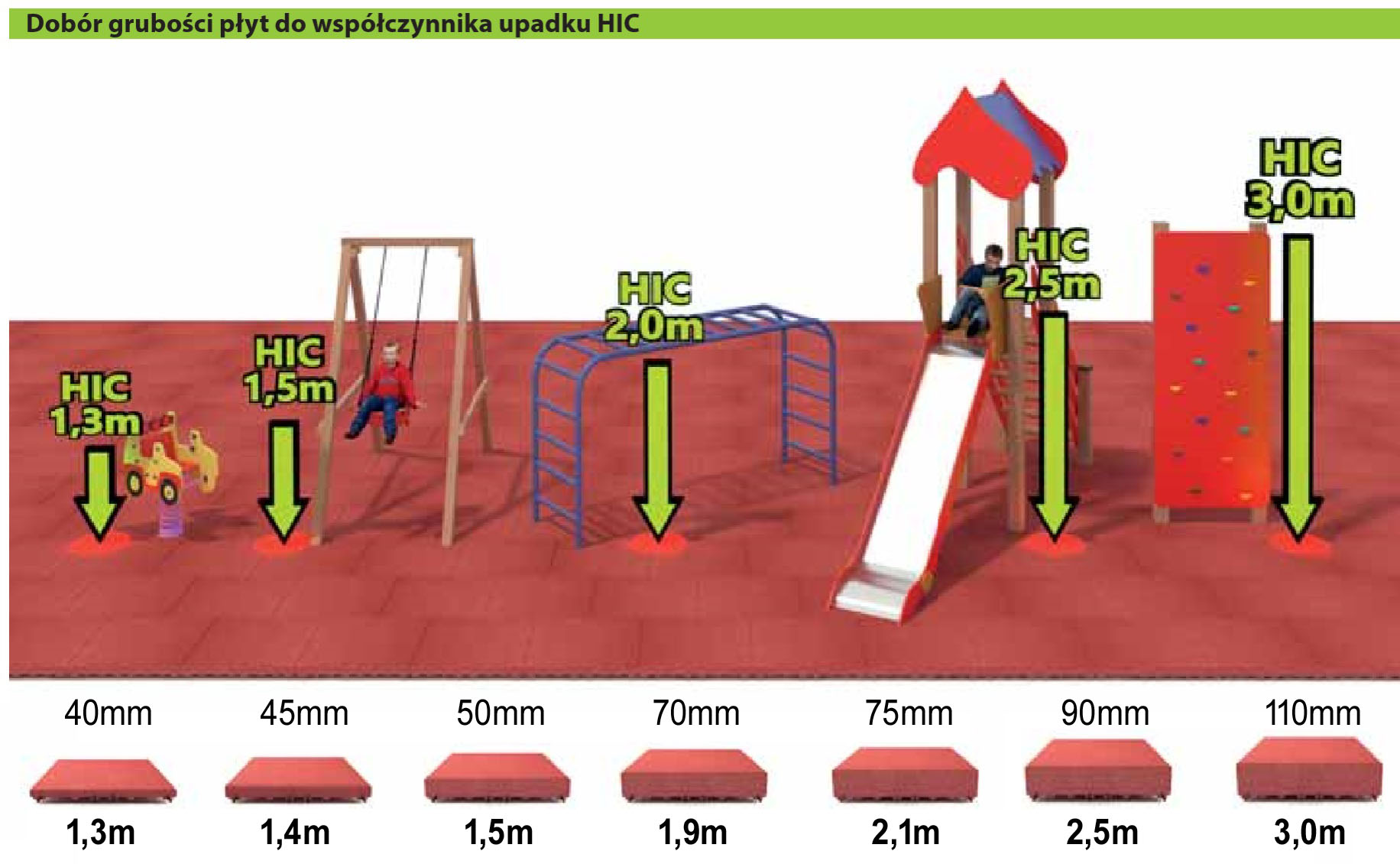

The Flexizone SBR tiles are produced in two standard sizes and in eight variants of tile thickness, which must always be adapted to the required HIC value (critical fall height). They can be installed in the standard or the so-called “folding” system.

16 points of corrugated pins guarantee a tight connection of the tiles and eliminate the effect of curling the edges. Proper surface preparation is of great importance. The ground should be level and stable.

We recommend watching the specially prepared instructional video.

- 500mm x 500mm

- 610 mm x 610 mm

Dimensions available:

- 500 mm x 500 mm

- 500 mm x 250 mm

- 500 mm x 125 mm

(All of the above tiles have chamfers on each side, which increases their mechanical resistance.)

- Dimensions 500 × 500 and 500 x 250 mm as sloping and corner panels.

Available thicknesses of FLEXIZONE rubber tiles:

40mm – HIC 1,3m

45mm – HIC 1,4m

50mm – HIC 1,5m

70mm – HIC 1,9m

75mm – HIC 2,1m

90mm – HIC 2,5m

110mm – HIC 3,0m